Safety guidelines for artists working from home

Artists can make use of many hazardous materials in their day-to-day work, such as solvents, resins, photography stock solutions, and paints and pigments. Other normally non-hazardous materials can pose health issues if not used correctly, such as sculpting materials (dusts from treated wood, stone, or plaster), fibers, and textiles. Even certain common household consumer products can be hazardous.

Fine Arts materials that may represent a health and safety risk if not used with proper ventilation include:

- Solvents: Solvents are used in many arts techniques, either as part of the art material itself (such as paints, inks, thinners or adhesives) or for cleaning up. The primary hazards are their flammability and solvent vapours, but many solvents are also toxic.

- Paints and Pigments: Paints and ceramic glazes contain a wide range of pigments, which may include heavy metals or other toxic metals to produce vivid colours.

- Photography solutions: The greatest risk involved with photographic processing is the mixing of the stock solutions. The chemicals used can vary, but can include toxic and/or corrosive substances.

- Wood, Stone and Other Sculpture Media: The primary hazards from woodworking and stonework are cuts and abrasions. However, the dust generated from the different work processes can cause irritation of the respiratory tract or asthma.

- Fibres and Textiles: Health hazards in fibre or textile arts include dusts, gases, fumes, and vapours that are inherent in the materials or are produced in the work process. These may be inhaled or affect the skin.

- Students are encouraged to get in touch with their faculty member or technician to go over their project and the steps that they have taken to improve health and safety in their home.

- Schedule regular breaks. Avoid working on projects for hours at a time without a break.

- Make sure to have access to basic first aid materials when working.

- Keep your workspace clean, uncluttered and organized: Make sure to have an easy egress without tight turns or congested manoeuvring areas.

- For easy cleanup, prepare your workspace by covering floors and tables with large and thick (6 mil) plastic sheets when required. Thinner material will tend to move around, fold or bunch up and could create a tripping hazard.

- Long hair must be put up or tied back and completely out of the way.

- No loose clothing (scarves, loose sleeves) or dangling jewelry (bracelets, necklaces) should be worn while working.

- If you can, get out of the house at least once a day. Your body needs to move, and fresh air and scenery is good for morale and productivity. Although we are practising social distancing, it is still important that you take a break from your routine workspace all while making sure to follow the directives communicated by the federal and provincial governments.

- If you are alone or self-quarantining, contact your professor to discuss alternatives.

There are three main routes of entry into the body: inhalation, dermal, and ingestion. Appropriate work methods, hygiene, and personal protective equipment must be considered to prevent exposures. Most homes will not have the proper ventilation for working with hazardous chemicals and dusts. However, there are precautions that can be taken to reduce the risk of exposure when handling hazardous materials.

- Ensure that you have the appropriate training:

- Workplace Hazardous Materials Information System (WHMIS) for Fine Arts (Mandatory)

- Hazardous Waste Disposal (Recommended)

- Assess the materials and their hazards. If labels do not have adequate information regarding contents, hazards, and precautions, consult the Safety Data Sheet (SDS) of the product. This document must be up-to-date (maximum of 5 years between the date of the last revision and the date of access), and be WHMIS 2015-compliant, with the required 16 headings. Most SDS are available online from the vendor or manufacturer of the material.

- Avoid using highly toxic materials at home.

- Open windows to provide natural ventilation and dilute the fumes generated by the use of chemicals.

- If possible, use a fan to move fumes/vapours away from yourself.

- Use a vacuum to simulate a dust collector for non-hazardous dusts.

- Avoid the use of solvents near heat sources or electrical equipment that could produce a spark.

- If possible, wear appropriate personal protective equipment (PPE) such as respirators, gloves, long sleeves and closed footwear.

- Any hair growth between the skin and face piece sealing surface of a respiratory device, such as stubble beard growth, beard, moustache or sideburns, will inhibit from a full respiratory protection.

- Never eat, drink, or smoke while working with hazardous materials.

- Do not use the same containers for paints, solvents, or other chemicals that you do for food or drink.

- If you must use food or drink containers, have a designated container for paints, solvents, or other chemicals and ensure to label it accordingly.

- Store materials safely. Do not keep arts materials in refrigerators that also contain food or drink.

- Dispose of any hazardous waste in a responsible manner. Never place hazardous chemicals in regular garbage or down the drain. Verify municipal guidelines to dispose of chemicals safely and consult the city of Montreal website for information on your local ecocentre.

- Solvent soaked rags can pose a serious fire hazard. Never leave solvent soaked rags out in the open for extended periods. Place solvent soaked rags in a garbage bag filled with enough water to completely cover the rags.

- Solvent containers should never be left open as vapours can be emitted and pose a fire hazard when mixed with air and in the presence of a source of ignition (i.e. heat, flame, spark, sunlight).

- Be mindful of others in your home. Although you may be protected with personal protective equipment, they can be exposed to the materials you are using. They should not be in the room with you as you work.

- Always wash your hands after working on your projects to avoid accidental ingestion of hazardous materials.

- Gloves should be changed at the first sign of degradation but also on a regular basis, even without visible contamination, ideally after a 2 hour-shift.

- Clean up when you are done for the day. Leaving spilled chemicals or hazardous dusts does not contribute to a healthy home environment.

Appendix 1: Safe work practices for specific tasks

Some Fine Arts activities require specific control measures, such as personal protective equipment (PPE) or efficient exhaust ventilation systems that are not necessarily available at home. It is strongly discouraged to carry out activities involving or generating hazardous chemicals, such as:

- the use of extremely corrosive chemicals, such as hydrofluoric acid (HF) solutions or concentrated acidic solutions and other mordants in etching processes (e.g. in printmaking, intaglio and lithography).

- curing procedures processed at high temperature in specific fuel-fired or electrical kilns that can release toxic combustion products (e.g. carbon monoxide, formaldehyde, sulfoxides).

Solvents are the most underestimated hazards used in the Arts. They can be used as is but are also mixed with oils, resins, varnishes, inks, additives, vehicles and binders, to name a few.

- Give priority to non-aromatic solvents and those generating zero (or low) Volatile Organic Compounds (VOCs)

- Do not wash plates or tools with solvents without appropriate personal protective equipment (gloves, safety glasses).

- Make sure that solvent containers are closed properly when not in use. In addition to potentially toxic emissions, solvent vapours are usually heavier than air and will tend to accumulate in lower areas in the room, where electrical outlets are located.

- Do not wash hands with solvents!

- Avoid the use of chlorinated waxes that are highly toxic and carcinogenic.

- Do not overheat wax to avoid the release of toxic fumes of acrolein.

- Heated wax is a fire hazard. Use a crock pot or an electric frying pan.

- Melting wax can emit highly irritating chemicals. Heat the wax to the minimum temperature required to melt and work outside, when possible. Iron off wax outside or, if a dedicated pot is available, melt it in boiling water, weigh down the fabric and let the pot cool so the wax solidifies on the top to reuse.

- Avoid the use of acetone, alcohol, benzene, or carbon tetrachloride to dissolve wax.

- Use appropriate storage/handling/disposable measures if solvents are used.

- Do not let solvent containers open and near ignition surce such as heat, a flame or an equipment that can provoke a spark or an electrostatic discharge.

- Use appropriate golves, eye and respitory protective devices while modeing waxes containing additives.

- Avoid the use of dry pigments containing carcinogenic lead, cadmium, chromium (VI) or mercury. Refer to the list of pigments provided in Appendix 2.

- Give priority to non-toxic paints to reduce exposure, allergies and chemical sensitivity: zero or low-VOCs, no heavy metals, no ammonia, no formaldehyde, and reduced amounts of toxic compounds.

- Consider the use of water–based paints.

- Toxic mists generated from spray guns, airbrushes, or aerosol spray cans require appropriate respiratory protective equipment. A half- or full-face respirator with suitable cartridges will be protective on the condition that the user has been fit-tested.

- Give priority to pre-mixed paints, water-based materials, non-toxic hues, commercially available inks.

- Use crayons and pastels that do not create dust.

- Wear personal protective equipment when handling solvents, paints, corrisives and when cleaning vrushes and other equipment.

- Wear protective safety glasses to avoid eye injury by projectiles.

- Clean up dust regularly. Never dry sweep as this will disperse the dust in the air. If possible, use a water spray while carving to minimize dust. Clean surfaces by wet mopping or vacuum.

- Avoid the following materials:

- Silica-containing stones such as sandstone, soapstone, slate, granite

- Asbestos-containing stones such as serpentine, soapstone and greenstone

- Hardwoods (giant sequoia, cork oak, some maple woods, redwood, ebony, blackwood, exotic woods, red cedar, oak, beech). Rather use softwoods, which are usually less toxic.

- Plaster containing silica or corrosive additives, such as Portland cement

- While the material itself may not be toxic, the presence of preservatives can contain toxic chemicals that can be released when manipulated.

- If possiblem work with local exhaust ventilation and dust collectors.

- Never burn wood treated with presevatives.

- Give priority to asbestos-free (alabaster) and low in silica (limestone) stones.

- Give priority to non-toxic glues and adhesives: white (polyvinyl acetate), water-based or casein glues.

- Do not use aromatic solvents to release molds.

- Avoid the use of polyester resins at home to prevent the build-up of harmful styrene emissions (toxic by skin contact and inhalation) and the presence of the catalyst MEKP (Methyl Ethyl Ketone Peroxide) that is highly flammable and explosive. The clear version of polyurethane resin is a similar health hazard.

- Use safe alternatives while working with resins and plastics such as Green polyurethaneTM, ArtResin®, or Aqua·Resin®.

- Pay attention to additives that often generate irritating and sensitizing compounds, such as rosin, petroleum jelly and other solvents.

- The sand used in molds can have high silica content: Use silica-free sands as much as possible and mix molding sand under local exhaust ventilation if possible. Otherwise, wear appropriate respiratory protection.

- When possible, use clean metal as feedstock as melting scrap metals can create toxic fumes from old paints, lubricants or coatings and lead, nickel, and chromium additives are hazardous to breathe.

- Avoid working with asbestos-containing mold releases.

- Pay attention to potentially toxic decomposition products when hot materials (e.g. metal) are poured down the sand molds containing organic resins and binders.

- Pigments containing arsenic, beryllium, cadmium, chromium (VI), nickel, uranium, antimony, vanadium, or lead are known or probable human carcinogens and are to be avoided at all costs. Refer to the list of pigments provided in Appendix 2.

- Consider dry clays as generating silica-related hazards and do not use them without appropriate personal protective equipment.

- Talc added to clay may contain asbestos or “asbestos-like fibers”. Respiratory protection must be worn while handling this type of material.

- Avoid the use of oil-based clays containing sulfurated derivatives.

- Wear appropriate gloves, safety glasses and respiratory protection while using wet clays as they represent growth media for molds and microorganisms that can provoke allergies, infections, or worsen asthma condition.

- Take necessary respiratory protective precautions during firing processes. Toxic gases including carbon monoxide, formaldehyde, sulfoxides, chlorine, or nitroxides can be released.

- For glazes: Ceramic stain, velvet underglazes, low fire glaze, and Raku glaze are recommended.

- Avoid the use of metal fluxes containing highly toxic compounds such as lead, barium, and lithium.

- Use boric oxide as a glass former instead of silica.

- Avoid the use of your pottery as a food/drink vessel as toxic chemicals can leach out.

- Firing processes in fuel-fired or electric kilns can release combustion products/gases, such as the toxic chemicals mentioned above, along with toxic compounds and infrared radiation. This process should be excluded from artistic activities from home.

- Use liquid chemistry rather than mixing developing powders, to avoid generation and inhalation of dusts.

- Developers may contain a variety of hazardous materials: skin and eye irritants and sensitizers (metol, organic amines), poisonous (catechol), mutagenic or carcinogenic chemicals (hydroquinone).

- Developing baths contain corrosive accelerators (sodium hydroxide) and may contain toxic antifogging agents or preservatives (potassium bromide, sodium sulfate).

- Stop/fixing baths may also contain corrosives (acetic acid) and toxic (potassium chrome alum, sulfur dioxide from sodium bisulfite decomposition) chemicals.

- Intensifiers and reducers can be carcinogens (potassium dichromate, chlorochromate), highly toxic (mercury and uranium intensifiers, cyanide reducers), corrosives (hydrochloric acid), or strong oxidizers (permanganates and persulfates).

- Toning may release highly toxic gases (hydrogen sulfide), sensitizing metals (gold, platinum), toxic selenium derivatives (hydrogen selenide), or carcinogens (thiourea).

- Colour developers are more hazardous than black and white developers. Elevated temperatures during the process lead to greater exposure to toxic di-amines and formaldehyde vapours.

- Do not use p-phenylenediamine and its derivatives.

- Use tongs to transfer from one bath to another.

- Cover all baths when not in use to limit the release of harmful vapours.

- Do not mix all baths together for disposal, and do not dispose of photographic chemicals via the sink.

- Always store corrosives on low shelves (below eye level) to prevent chemical splash to the face and eyes.

- Wear appropriate personal protective equipment (PPE) including safety glasses and thick gloves while handling developers, intensifiers/reducers, or corrosive developing and stop/fixing baths.

- Appropriate ventilation is required in dark rooms to control the level of toxic vapours.

- The use of toxic and corrosive materials involved in the different photography processes is strongly discouraged in the absence of engineering controls such as local exhaust ventilation.

- Corrosives (both acids and caustics) are used extensively in etching and cleaning processes in intaglio and lithography. Avoid the use of strong corrosives in the home environment.

- Always consult the SDS before working with a corrosive to make sure you have the right personal protective equipment (PPE) to protect your skin, eyes, and respiratory tract. Gloves, goggles, an apron, and a respirator with appropriate filter cartridges may be required.

- Dilute corrosives safely: slowly add the corrosive to water, a little at a time. Adding it too quickly or in the reverse order can create a lot of heat and cause unexpected splashes.

- Use ferric chloride instead of Dutch mordant for etching copper plates. Although both solutions are corrosive, ferric chloride is less toxic and less hazardous.

- Use grounds, stop-outs, and acid etching only in well-ventilated areas.

- Pigments, solvents, dyes and inks can be toxic. Avoid any that contain lead or chrome, and use non-toxic or less-toxic alternatives. Wear gloves to avoid contact between skin and these materials.

- Avoid mixing dry pigments, in order to prevent dust generation and inhalation. Even non-toxic dusts may cause irritation of the respiratory tract or more serious reactions.

- Some printing media may support bacterial growth. Be aware of the potential for exposure when these media are expired, contaminated, or improperly stored. Bactericidal agents used to preserve media may themselves be hazardous.

- Hot-casting, electrotype processing, and photographic plate development may involve lead, nickel, or other metal salts, which present a chronic toxic hazard.

- Open flames are a fire hazard. Never use an open flame to heat linseed oil, solvents, flammables, combustibles, or any other materials.

- Do not overheat materials, as decomposition at high temperatures may generate toxic gases.

- Oil- and solvent-soaked rags may ignite by spontaneous combustion. Place used rags in a plastic garbage bag, and add enough water to cover them.

- Cleaners may contain chlorinated hydrocarbons, which are suspected human carcinogens. Consult the SDS of any material you use for safety precautions, including cleaners.

- Consider the physical hazards of the tools used, such as sharp edges and moving parts with the potential to crush, shear, or cut. Scissors, staplers, cutting blades, binding machines, and paper trimmers could all cause injury. Never place your hand in the path of a tool, and always cut away from the body.

- Use low-dusting dyes and pigments, dust suppressed such as solutions, water dispersions, granules, pellets, paste.

- Powdered union dyes from the consumer market can be as hazardous as professional dyes.

- Engineering controls (e.g. glove box) and PPE (respiratory devices) are required when an activity generates dust.

- Never use techniques that raise dust or produce a mist such as sprinkling dye or using an airbrush without access to a local exhaust ventilation system and fitted PPE.

- Avoid the use of hazardous mordants (e.g. fixatives containing chromium dyes).

- Do not use the same containers and utensils to prepare textile pastes and food. Do not store hazardous materials in your fridge. Wet mop the workspace at the end of each work session.

- PPE must be worn when handling dyestuffs, dye auxiliaries or sensitizing cellulosic fibres (spinning, weaving, sewing, cutting for use in paper, flock application).

- Stick to water-based inks and photo emulsion for silk screening.

- Use stencils or a thermofax machine to produce photo stencils in order to avoid the reclaiming products necessary when using photo emulsion.

- If spotting solvents are required, non-halogenated alternatives are preferred.

- Using electrical equipment in a wet environment presents a risk of electrocution. Ensure hands are dry when touching outlets and electric cords. Lift cords away from wet surfaces and contain water spills.

- Dry harvested fibres quickly, and do not store them in closed bags unless they are completely dry.

- Change pulp water frequently and do not use musty or mildewed materials to avoid exposure to fungi spores.

- Recycled commercial paper pulp will contain a variety of additives. Protect your hands when working with them.

- Working with feathers and hair harvested from diseased animals can cause zoonosis. Stick to disinfected and washed fibres.

- Take frequent breaks to avoid repetitive motion injuries (weaving, sewing, machine knitting, needlework, crochet, needle felting, etc.).

- Work outside and protect skin and eyes if cooking papermaking fibres in alkaline solution. Allow fibres to cool in pot to avoid thermal burns. Ensure water is close by in case of a thermal or chemical burn.

- Tie back long hair, remove dangling jewelry and secure loose clothing when operating motorized rotary equipment.

- Always use lead-free solder.

- Always work in a well-ventilated space.

- Keep the sponge wet while soldering or use brass sponge.

- Ensure the tips of your iron are clean.

- Only use sponges meant for soldering purposes.

- Use protective gloves and safety glasses while soldering.

- Use tweezers or clamps to hold the wires to be heated.

- Always put the soldering pen back on its stand when not in use.

- Turn off or unplug the soldering station when not in use.

- Never touch the tip of the soldering iron; the temperature can easily reach 350-400°C.

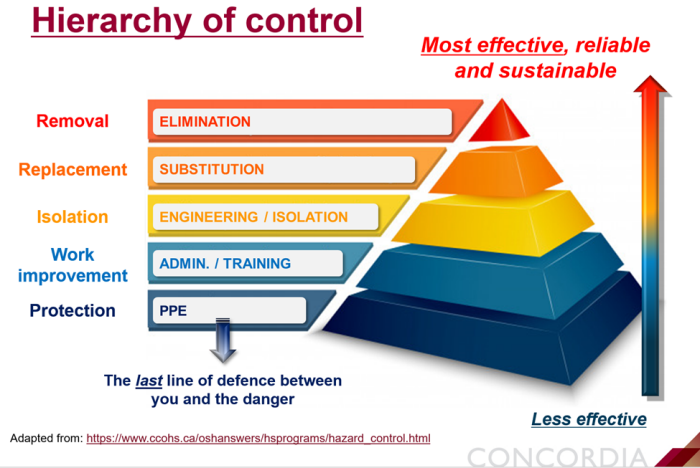

Hierarchy of Controls

Controlling exposures to hazards is the fundamental method of protecting workers and students. Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective control solutions.

Although some sources may use additional levels and a variation of the hierarchy of controls, it is widely accepted that there are at least five main ways to control a hazard (see Figure 1). The concept behind this hierarchy is that the control methods at the top of graphic are potentially more effective and protective than those at the bottom.

Figure 1

1. Elimination

This is the process of removing the hazard from the workspace. It is the most effective way to control a risk, although not always feasible.

2. Substitution

Involves substituting hazardous materials, machines or equipment with less hazardous ones. For this to be effective, the user must evaluate the hazards related to the products to be substituted along with the ones associated with potential substitutions. That is, one hazard must not be traded for one of equal or more hazardous properties. Very often, Safety Data Sheets comparison is useful in this process.

Common non-hazardous alternatives include:

- Non-toxic pigments

- Non-aromatic solvents

- Water-based paints

- Low VOC paints

- Pellets, crystals, flakes instead of fine powders

3. Engineering controls

Engineering controls include methods built into the design of an equipment or a process to minimize the hazard. Process control, enclosure and ventilation are among the most efficient ways to control and mitigate chemical exposures. However, this type of control is the most difficult to achieve while working at home. Some process controls such as wet method, steam cleaning can easily be applied but the use of methods aiming to enclose, isolate the chemicals from the user or properly ventilate the workspace (general or local exhaust) often require specific techniques or equipment that are not available at home.

4. Administrative controls and training

These control measures are intended to improve users’ work practices by creating and implementing standard operating procedures (SOP), guidelines, training programs, and appropriate signage. The hazard itself is not actually removed or reduced. However, training and education about the operating procedures (handling, storage, disposal), good housekeeping programs, the maintenance of equipment, along with the awareness/preparedness in case of emergency (spills, fire, injury) and the adequate personal hygiene practices are essential to control and mitigate hazardous exposures.

5. Personal Protective Equipment (PPE)

Contrary to preconceived notions, PPE do not represent the best method for protection from the hazards but are an alternative in the absence of elaborate engineering control systems and when elimination and substitution is not feasible. PPE is considered as the last line of defence between the individual and the hazard. PPE includes respirators/dust masks, gloves, eye protection, protective clothing, and footwear. PPE should never be the only method used to reduce exposure but rather a combination with other control measures. One type or brand of PPE does not protect against all hazards. The selection will depend on the type of activities and the hazards generated and a combination of PPE is often required. Contact EHS for help in choosing appropriate PPE.

Appendix 2: Pigments

- Antimony white - White 11 (antimony trioxide)

- Barium yellow - Yellow 31 (barium chromate)

- Burnt umber or raw umber (iron oxides, manganese silicates or dioxide)

- Cadmium red or orange - Red 108 and Orange 20 (cadmium sulfide, cadmium selenide)

- Cadmium yellow - Yellow 37 (cadmium sulfide)

- Cadmium barium colours (cadmium colours and barium sulfate)

- Cadmium barium yellow - Yellow 35 (cadmium sulfide/selenide, barium sulfate, zinc sulfide)

- Chrome green - Green 15 (Prussian blue, lead chromate)

- Chrome orange - Orange 21 (basic lead carbonate)

- Chrome yellow - Yellow 34 (lead chromate)

- Cobalt violet - Violet 14 (cobalt arsenate or cobalt phosphate)

- Cobalt Yellow - Yellow 40 (potassium cobalt nitrate)

- Emerald green - Green 21 (arsenite)

- King's yellow - Yellow 39 (arsenic)

- Lead or flake white - White 1 (basic lead carbonate)

- Lead red - Red 105 (lead)

- Lithol red - Red 49 (sodium, barium and calcium salts of soluble azo pigment)

- Manganese violet - Violet 16 (manganese ammonium pyrophosphate)

- Mercadium orange - Orange 23 (cadmium, mercury and sulfides)

- Molybdate orange - Orange 45 (lead chromate, lead molybdate, lead sulfate)

- Naples yellow - Yellow 41 (lead antimonate)

- Strontium yellow - Yellow 32 (strontium chromate)

- Vermillon - Red 106 (mercuric sulfide)

- Zinc sulfide white - White 10 (barium)

- Zinc yellow - Yellow 36 (zinc chromate)

- Alizarin crimson (flakes of 1,2-dihydroxyanthraquinone or insoluble anthraquinone pigments)

- Carbon black (carbon)

- Cerulean blue - Blue 36 (cobalt stannate)

- Cobalt blue - Blue 28 (cobalt stannate)

- Cobalt green - Green 19 (calcined cobalt, zinc and aluminium oxides)

- Chromium oxide green - Green 17 (chromic oxide)

- Manganese blue - Blue 33 (barium manganate, barium sulfate)

- Manganese violet - Violet 16 (manganese and barium)

- Prussian blue - Blue 27 (ferric ferrocyanide)

- Toluidine red - Red 3 and 147 (insoluble azo pigment)

- Viridian - Green 18 (hydrated chromic oxide)

- Zinc white - White 4 (zinc oxide)