“The aim of the project was to reduce risk,” says Lina Filacchione, manager of occupational health and safety in Environmental Health and Safety. “This involved installing movable Lexan screens at the most strategic points, as well as delimiting a safety zone.”

Four eight-foot polycarbonate panels were installed in stages on the sides of the press. The team left a two-inch gap at the bottom of the panels to ensure good air circulation during testing. The gap also makes it easier for users to clear away debris, as well as hoses and cables for data collection and controls.

A combination of steel and aluminum hardware hold the panels in place, which is attached to the press with steel brackets.

“Structural test operators can move the guarding panels easily and safely to place and remove test specimens and make adjustments to the testing machine,” Galal says.

“This is notable because it was impossible to find a similar product on the market due to its complexity. Unlike traditional installations, the guards have been designed to maintain visibility throughout testing, while ensuring the safety of students and staff.”

From left: Mohamed Aiyar (CNESST), Pietro Gasparrini (EHS), Khaled Galal (BCEE, GCS) and Alexis Gosselin (GCS)

From left: Mohamed Aiyar (CNESST), Pietro Gasparrini (EHS), Khaled Galal (BCEE, GCS) and Alexis Gosselin (GCS)

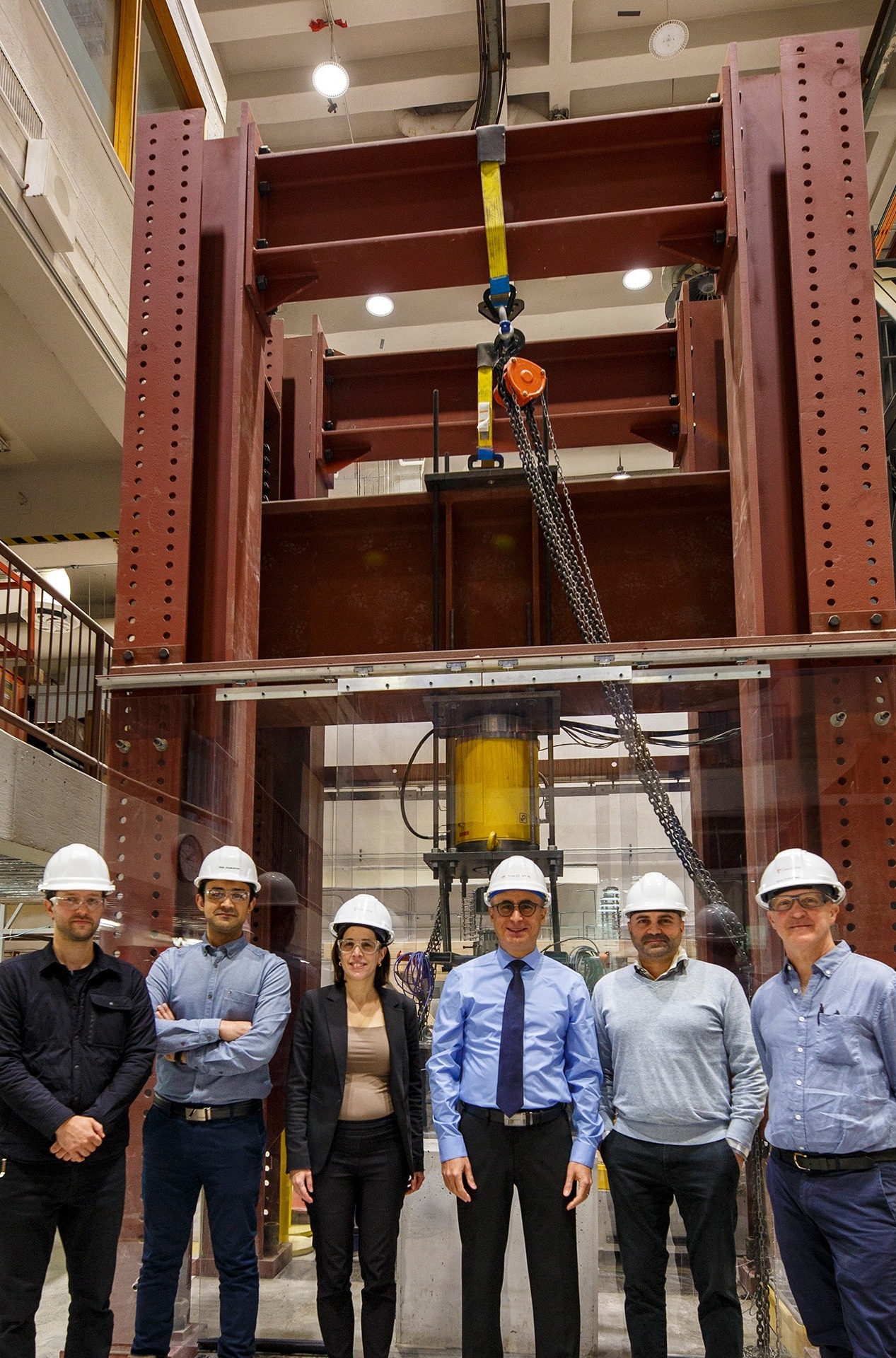

From left: Alexis Gosselin (GCS), Belal Abdelrahman (BCEE, GCS), Lina Filacchione (EHS), Khaled Galal (BCEE, GCS), Riccardo Gioia (GCS) and Duncan Chisholm (GCS)

From left: Alexis Gosselin (GCS), Belal Abdelrahman (BCEE, GCS), Lina Filacchione (EHS), Khaled Galal (BCEE, GCS), Riccardo Gioia (GCS) and Duncan Chisholm (GCS)

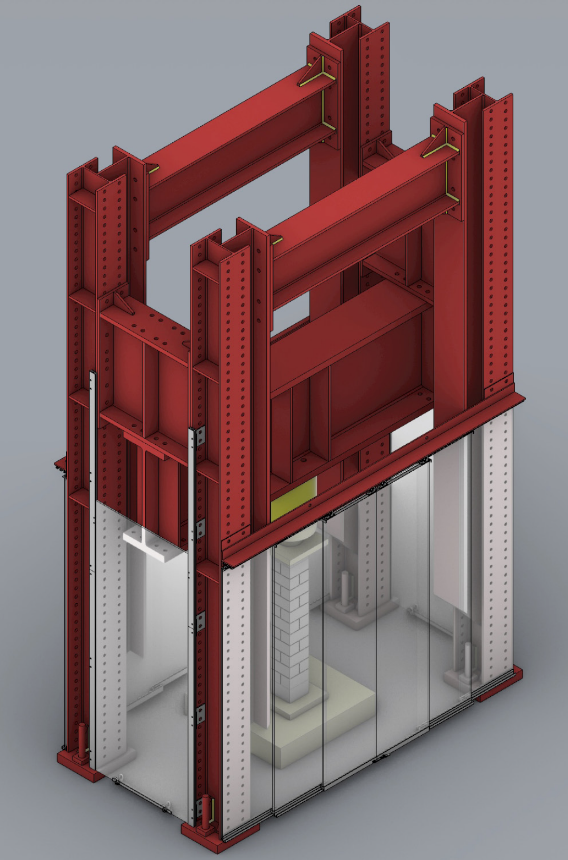

A rendering of the modified high-capacity testing frame.

A rendering of the modified high-capacity testing frame.

The plaque presented to Concordia by the CNESST.

The plaque presented to Concordia by the CNESST.