Funded by CFI, NSERC, FQRNT and industry, the upgraded Structures and Infrastructure Testing Laboratory at Concordia is a state-of-the-art structural testing facility. The facility can test different structural elements and assemblages, including columns, bridge girders, frames and walls made of concrete, masonry, steel or their combinations. The testing mode could be static, cyclic or dynamic (to simulate the wind or seismic forces).

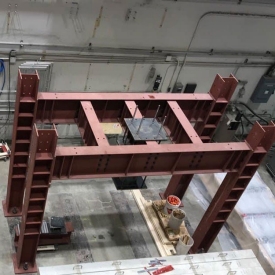

The lab has a strong frame equipped with three servo-hydraulic actuators, an MTS digital servo-controller, two hydraulic service manifolds and a high-capacity hydraulic power unit. This new test system is capable of large-scale static and dynamic structural simulation and applies precise variable loads both vertically and horizontally.

Each heavy-duty, double-acting, servo-hydraulic actuator can apply force up to 1000 kN in either compression or tension. They are equipped with precision computer-controlled servo valves, LVDTs for measuring the displacement and load cells for measuring the force. Swivel bases and rod ends provide pivotal freedom at both ends of the actuators. The servo-controller combines precise, real-time, closed-loop control and function generation to drive the system’s hydraulic and mechanical components. The testing facility also includes the wireless strain and acceleration sensors and data acquisition for fiber optic and wireless sensors, particularly useful for an on-site assessment and structural health monitoring of existing structures.