Lucas Hof is PhD candidate at Mechanical Engineering, Concordia University. Together with Dr. Rolf Wüthrich and Posalux SA, he has co-developed a novel glass micromachining technology allowing the lean production of ultra-customized glass parts. To this day, Hof has cumulated over 10 years of teaching, entrepreneurial and industrial experience and produced over 30 journal and conference papers and one patent.

Blog post

Suitable fabrication technologies for Industry 4.0 – an introduction to 3D printing

Industry 4.0 is a possible answer to produce mass-personalized products economically. It promotes the computerization of manufacturing. The goal is to develop Smart Factories, where the complete manufacturing chain communicates via the Internet of Things, ultimately producing an economically produced Batch Size 1 (one unique product).

But what kind of manufacturing processes integrate well in this new approach?

As discussed in previous blogs, as the industry 4.0 paradigm will be implemented progressively across global companies, the manufacturing industry must deal with situations where geometry of the sub-parts changes as well. In this case the customer will not only choose from existing options but will be actively involved in the design. In such cases of mass personalization new manufacturing technologies are required which can keep manufacturing overhead related to change of part geometries low. They need to address the issues of tooling costs (avoid part-specific tooling) able to handle complex parts and reduce production steps (eliminate overhead due for example to alignment or tool change).

A good example of a fabrication technology meeting these requirements is 3D printing or additive manufacturing. In 3D printing, an object (part) is created layer by layer using a digital 3D model of the object you want to create. This model is first sliced into thousands of tiny little slices by slicing software (see here for an overview of (mostly free) slicer software tools) and converted into coordinates and additional data for the printer, so it knows how and where the material should go layer wise. In fact, you can imagine the process as making a loaf of sliced bread in reverse. Imagine you first bake each individual slice of bread, which you then glue together to get the whole loaf. This is the opposite way as the way it is done by a baker, who makes the whole loaf and then slices it.

Costs of 3D printers can range from a few hundred dollars for a simple hobby printer printing plastic to a million-dollar machine with high precision and able to print metals for industrial grade products.

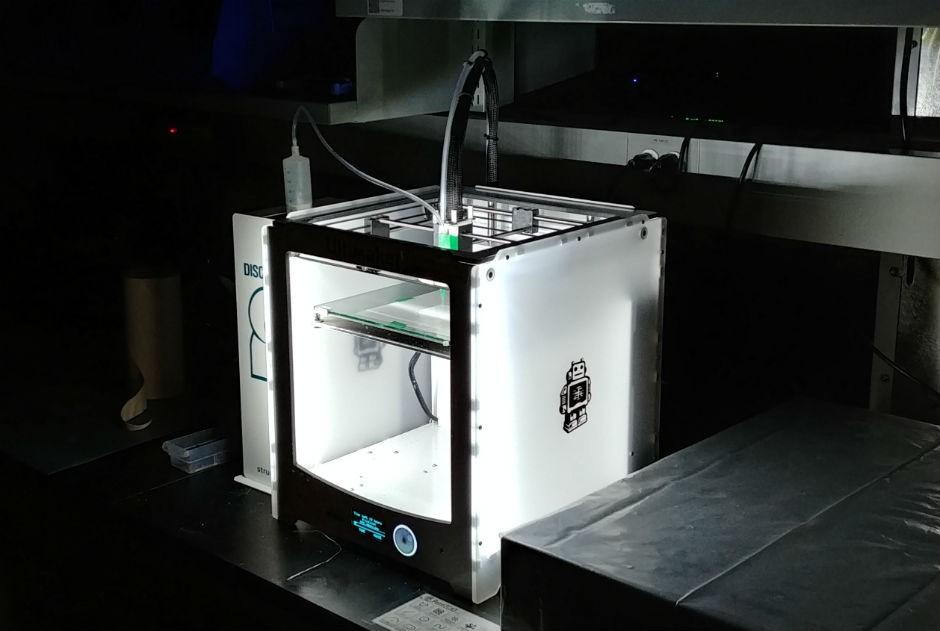

The most popular hobbyist-grade 3D printing process is fused filament fabrication (FFF) or fused deposition modeling (FDM). Here, a thermoplastic material (often acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) material) is fed through an extruder system which pulls/pushes the material through a heated nozzle with a small opening (typically around 0.4 mm) enabling the material to flow on a platform. This nozzle can be moved horizontally by (stepper) motors to make the needed pattern as read from the sliced information. Vertical movement of the platform in small steps allows then for building up the model layer by layer and at the end your 3D model is realized. Limits on geometries to fabricate in this way are less than in traditional methods such as milling, although supports are needed for more complicated models with large overhangs. The support removal is largely material dependent and ranges from simple to complicated methods. More research is needed to overcome these limits for 3D printing and developing advanced post-process technologies to give your parts the surface finish you want.

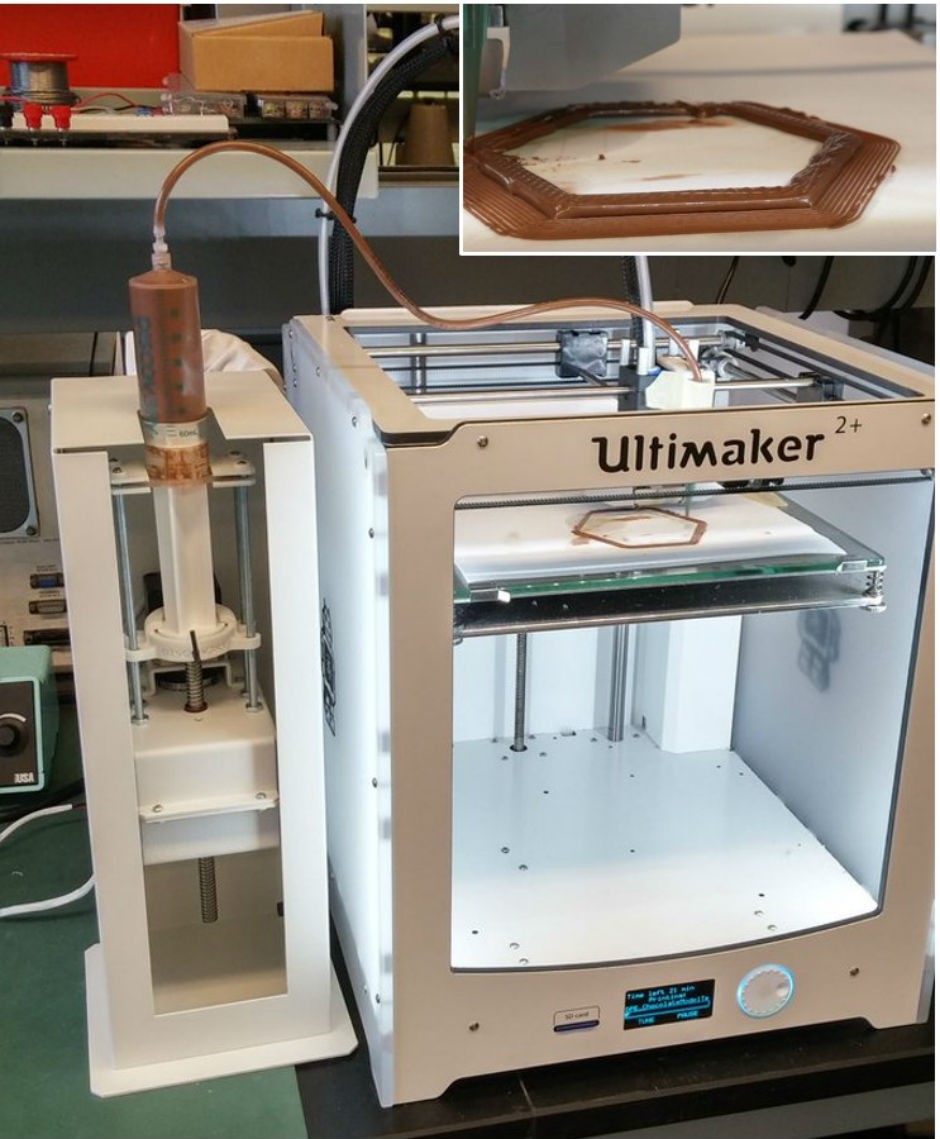

Using additional systems as the paste extruder gives you even more material options for 3D printing. In the picture below you see an example of 3D printing with chocolate (Nutella) at our lab to engineer your confectionery.

An extensive guide to determine which printer will be best for your application/needs and budget is provided by the 3D printing platform 3D hubs (find the book here). It is based on more than 10,000 reviews from 3D printer users. Some guidelines and most important elements of 3D printing are detailed in their developed 3D printing handbook.

About the author