Lucas Hof is PhD candidate at Mechanical Engineering, Concordia University. Together with Dr. Rolf Wüthrich and Posalux SA, he has co-developed a novel glass micromachining technology allowing the lean production of ultra-customized glass parts. To this day, Hof has cumulated over 10 years of teaching, entrepreneurial and industrial experience and produced over 30 journal and conference papers and one patent.

Blog post

The start of a new industrial revolution...

Smartphones. Tablets. Laptops. Cars. Bikes. Home appliances. We use most of these products daily and it’s hard to imagine a world without these products…. but have you ever thought of how these products are made and constantly renewed and adapted to our current needs?

Welcome to the world of manufacturing!

As engine of the global economy, it is the manufacturing industry that enables us to have our current, constantly increasing, standard of living.

The Fourth Industrial Revolution

Within the past two centuries, we passed through three industrial revolutions leading us to the ability to mass produce complex products in affordable ways like cars and smartphones. Mostly due to technological advances and the demand for personalized products, manufacturing industry is at the start of a new industrial revolution and opening up many new possibilities and challenges. We have yet to understand fully the speed and extent of this new revolution often referred to as the fourth industrial revolution. Think of the unlimited possibilities of having an enormous amount of people connected globally by mobile devices generating lots of data, together with breakthroughs of emerging technologies in diverse fields including among others: artificial intelligence (AI), the internet of things (IoT), 3D printing, autonomous vehicles robotics, nanotechnology, energy storage and materials science. This will impact and change the way we live, work and relate to one another.

Industry 4.0

In Germany the term “Industry 4.0” was launched at the Hannover fair in 2011 to describe how this will revolutionize the organization of global value chains. Industry 4.0 aims to develop smart factories in which the production of low volume, mass-personalized goods, is possible in economical ways. Key is to go beyond automatization and make intensive use of modern IT technologies across the full chain from the order of the customer, passing by machining and production to the delivery of the finished product.

While lots of research is currently ongoing on many elements of Industry 4.0 like big data, robotics, machine learning, cybersecurity, and system optimization, not so much research is done on the manufacturing processes itself.

Research on Advanced Manufacturing

My research aims to contribute in developing novel advanced manufacturing processes which support Industry 4.0. According to a recent case study made for the World Economic Forum, hybrid technologies, in particular electrochemical technologies (using both electricity and chemistry), would have a great potential towards this aim. Such processes require little to no specialized tooling and are able to handle virtually any shape.

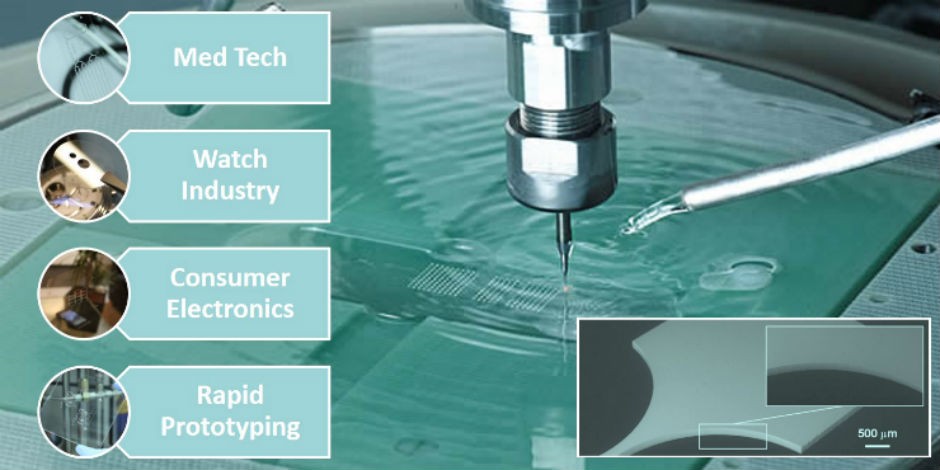

High precision machining of glass by SACE and its application markets

High precision machining of glass by SACE and its application markets

Ongoing research conducted at the Centre for Advanced Manufacturing at Concordia University shows promising results of implementing these electrochemical processes to fabricate personalized products. We developed further a novel hybrid manufacturing technique to process glass: Spark Assisted Chemical Engraving. Glass is selected because of the increase in demand for glass-based devices (e.g. for bio-sensors, smartphones) and because it is difficult to machine, resulting in the knowledge generated by this research being transferable to other materials. Other technologies are also developed by our team like electrochemical polishing to finish metal 3D printed parts. As these parts have generally complex shapes, methods for surface finishing become difficult to identify.

In upcoming blogs I will write more on the fourth industrial revolution, our advanced manufacturing technologies, and its applications. Please feel free to contact me if you want more information on these topics.

About the author