EQUIPMENT

The Concordia Materials Characterization Platform (CMCP) brings together a unique collection of instruments and analytical tools to analyze a wide range of materials, with a special focus on aerospace, energy and environmental applications.

It includes analytical and imaging instrumentation to help carry out novel research in many areas such as advanced materials, coatings and surface treatments, environmental studies and nanotechnology.

Equipment has been sourced from around the world thanks to funding from the Canada Foundation for Innovation, the Natural Sciences and Engineering Research Council of Canada, and the Fonds de recherche du Québec – Nature et technologies (FRQNT).

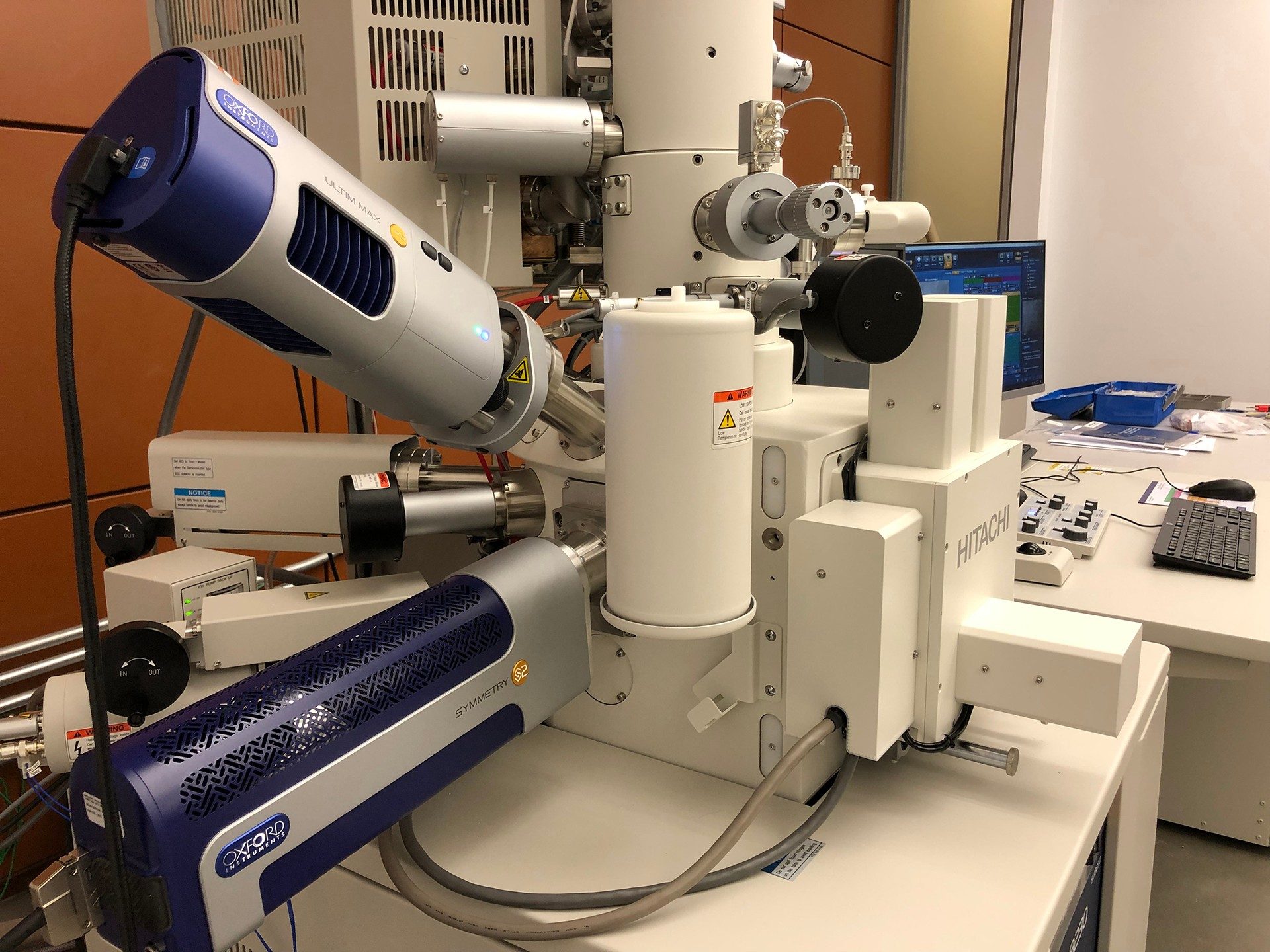

Ultra-High Resolution Scanning Transmission Electron Microscope (STEM)

This microscope uses a Cold Field Emission source which is ideal for ultra-high-resolution imaging and is equipped with STEM, EDS and EBSD.

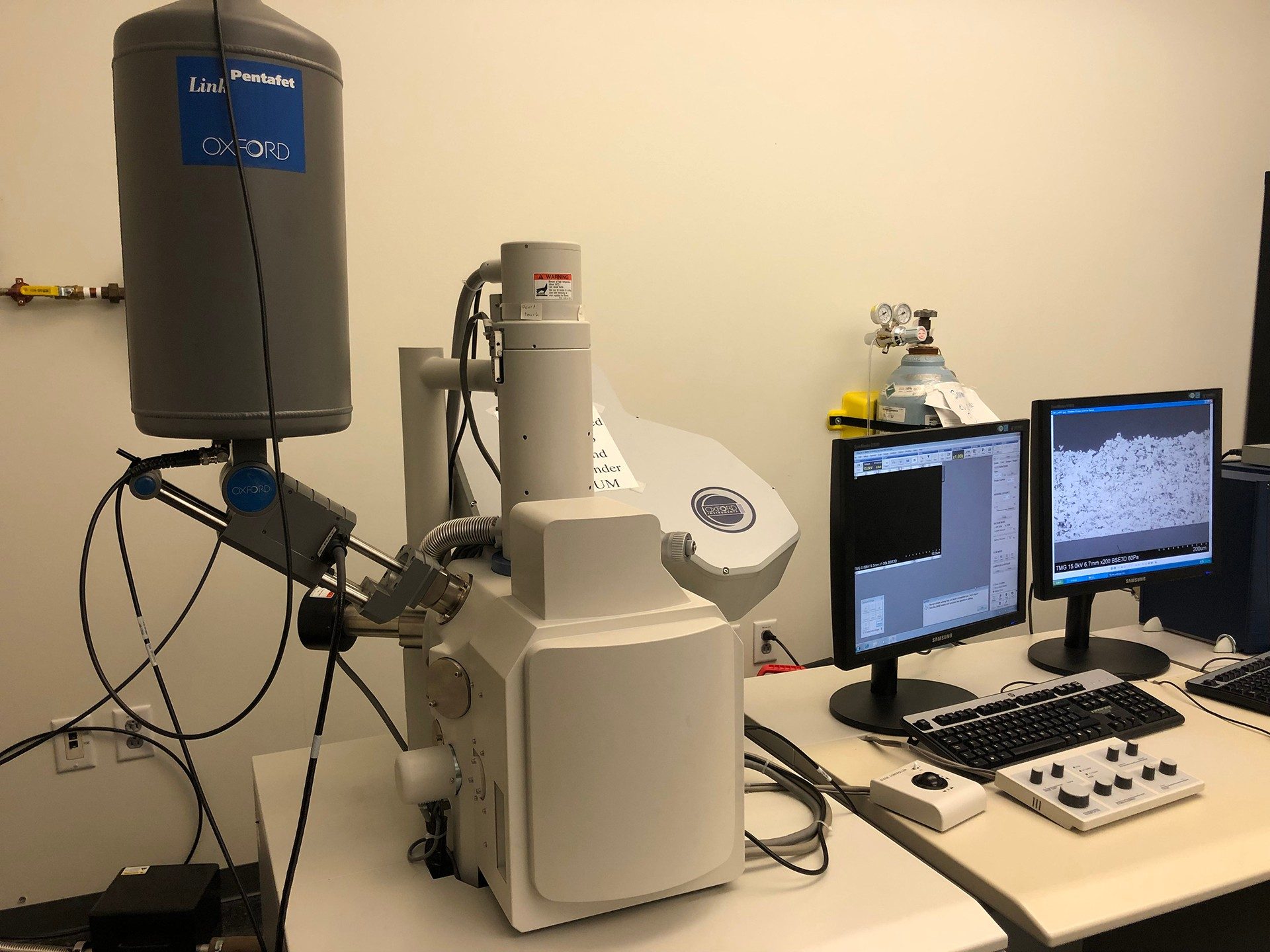

Environmental Scanning Electron Microscope (ESEM)

This is a variable pressure electron microscope equipped with WDS and EDS.

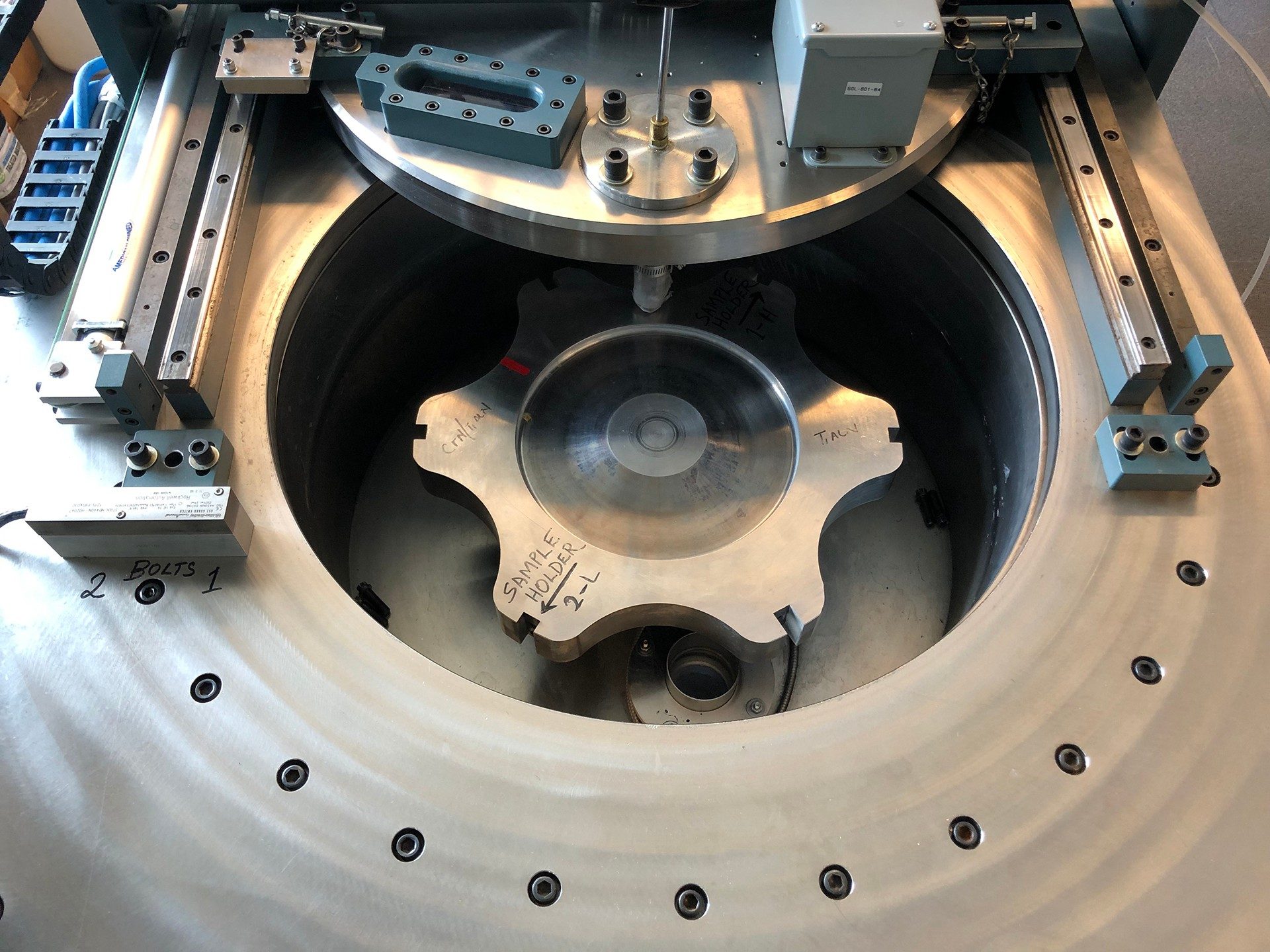

Water Droplet Erosion Rig

Liquid impingement erosion tests can be done using this facility at two different speed ranges, low speed (up to 350 m/s) and high speed (up to 500m/s).

Water Droplet Erosion (WDE) Tester

The Water Droplet Erosion (WDE) Tester provides an efficient and practical method for directly simulating the impact of water droplet-induced erosion on materials. It enables to study erosion mechanisms under controlled conditions that closely mimic real-world scenarios.

X-Ray Diffractometer (XRD) with micro-XRD

X-ray diffractometry is used to determine the available phases, their relative amounts and provide information on their crystal structures. A micro-XRD system focuses the X-ray beam to a very small spot (0.5x3 mm), allowing diffraction analysis of tiny regions or individual grains. It can be used to study phase composition, stress, and texture in heterogeneous materials, coatings, thin films, or inclusions.

High Temperature X-Ray Diffractometer (XRD)

An X-ray diffractometer with a hot chamber allows in-situ study of structural changes in materials at elevated temperatures up to 1500 °C. This setup is used for studying phase transformations, thermal expansion, crystallization, and decomposition. It enables real-time monitoring and provides direct insight into how crystal structures evolve at various thermal conditions.

Mercury Porosimeter

A mercury intrusion porosimeter measures the pore size distribution and porosity of a material by forcing mercury into its pores under controlled pressure. By recording the volume of mercury intruded at each pressure, the instrument calculates pore size, pore volume, and surface area. This technique is useful for studying ceramics, catalysts, rocks, membranes, and construction materials. It provides valuable information about material performance related to permeability, strength, and adsorption capacity.

Thermal Conductivity Analyzer

Versatile system enabling precise thermal conductivity measurements of solids, liquids, powders and pastes.

Rotating Beam Fatigue Testing Machine

Performs high-cycle rotating beam fatigue tests with automatic loading and breakage detection.

Hydrogen Analyzer

Determines hydrogen content in metals using heat extraction with high precision.

Oxygen/Nitrogen/Hydrogen (ONH) Analyzer

Accurately measures oxygen, nitrogen, and hydrogen content in materials such as metals, ceramics, minerals, catalysts, rubber, and more using fusion extraction and thermal conductivity detection.

Carbon/Sulfur (CS) Analyzer

Measures carbon and sulfur content in materials such as metals, ceramics, and minerals using combustion and infrared detection for accurate and reliable analysis.

Small-Scale Shear Punch Testing

Performs small-scale punch testing on metals using a universal testing machine to evaluate mechanical properties with minimal material requirements.

Thermal Cycling Rig

This equipment will allow samples to be subjected to long cycles of heating and cooling that accurately simulate thermal conditions within a turbine or a jet engine.

Ultra-High Temperature Differential Thermal Analyzer (TGA)

This machine is the standard for high performance TGA, TG-DSC and TG-DTA application up to 2000°C.

Specialized equipment

Metallographic Optical Microscope (MOM)

The MOM is a tool that uses a reflected light technique to examine the microstructure of polished metal or alloy samples, allowing analysis of grain structure, phases, and defects at the microscopic level.

Metallographic Polishing Equipment

The grinding and polishing equipment are for metallographic sample prep, from hand grinders to automated systems. They ensure precise, efficient performance and high-quality results across a range of materials.

Glove box for Li-batteries applications

Which include: development, manufacturing, and testing of lithium-ion batteries to create a pure, controlled, and moisture- and oxygen-free environment.

Microwave Furnace for Metal Casting

A specialized type of furnace that uses microwave energy to generate heat for various industrial and laboratory applications. Unlike traditional furnaces that rely on combustion or electric resistance heating, microwave furnaces utilize electromagnetic waves to directly heat materials.

Induction, Tube and Box Furnaces

Induction furnaces use electromagnetic fields for high-efficiency heating and melting, while tube furnaces provide controlled, uniform heat in a cylindrical chamber ideal for material synthesis and testing, and box furnaces feature a rectangular chamber for processes like annealing, heat-treating, and sintering in various industrial.

Vickers Micro-Hardness Tester

The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness.

Laser Confocal Microscope

The Olympus Lext 4000 confocal microscope 405nm laser uses a reflected light to view 2D and 3D topographical images of inert samples.

Vickers Micro-Hardness Tester

The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness.

Equipment access

All CMCP instrumentation is available for external use, and the platform welcomes clients from across the scientific community, universities, research institutes and industry.

The breadth and quality of the equipment has attracted both local and international users.

For information on materials access and pricing, please contact Mazen Samara at mazen.samara@concordia.ca or 438-372-3269.