Engineering solutions: from in-house composting to smarter skis

So many young minds, so many great ideas.

The atrium of the Engineering, Computer Science and Visual Arts Integrated Complex bustled with excitement last Wednesday and Thursday as undergraduate engineering students presented their Capstone projects — supervised design, simulation or experimental undertakings that involve defining a specific problem, carrying out the research, designing a solution and demonstrating results.

All final-year students in Concordia’s Faculty of Engineering and Computer Science must complete a Capstone project. It’s a chance for them to participate in leading-edge research while working in a team to design something from scratch. It also tests their project-management, technical-writing and presentation skills.

Eighty-six projects created during the 2015-16 academic year were on display. Teams of smartly dressed students eagerly explained their work to passersby. Here is a sampling of their Capstone initiatives:

Schedule optimization of the Montreal Jewish General Hospital’s Department of Oncology

It’s all about timing. A team of six industrial engineering students took it upon themselves to improve the scheduling process for oncology patients at Montreal’s Jewish General Hospital.

“The chemotherapy chairs were underutilized,” says Eric Morneault, team spokesperson. “The problem was the scheduling — it was done manually, which is time consuming and vulnerable to human error. The scheduling was also done throughout the week, so once you made an appointment, it couldn’t be changed.”

The existing system created gaps, Morneault says. His team figured out how to fill them.

“We created scheduling software and recommended doing all of the upcoming week’s scheduling at once, at the end of the week, for greater optimization of chair usage.”

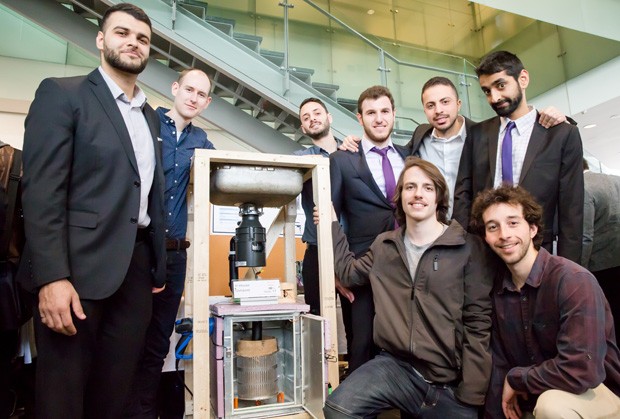

“We want to decrease the ‘yuck factor’ of composting at home,” says Dylan King, one of eight mechanical engineering students who worked on this Capstone project. | All images by Emily Gan

“We want to decrease the ‘yuck factor’ of composting at home,” says Dylan King, one of eight mechanical engineering students who worked on this Capstone project. | All images by Emily Gan

In-home compost

“We want to decrease the ‘yuck factor’ of composting at home,” says Dylan King, one of eight mechanical engineering students who aimed to improve home-composting options. “We want to make it easier and affordable.”

To do that, the students wanted to incorporate existing garburator technology. However, garburators that feed into the sewer system will soon be illegal.

As a solution, the students’ garburator feeds into a box lined with burlap and warmed with a heat gun. Once the biodegradable content is fully composted, the container can be dumped outside, into a garden. The market price is competitive at $330.

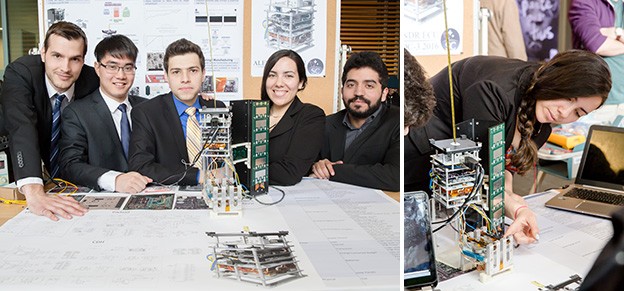

Nathaly Arraiz (far right) explains how her team power a miniaturized satellite called a CubeSat.

Nathaly Arraiz (far right) explains how her team power a miniaturized satellite called a CubeSat.

Electronic control unit for a CubeSat

Several of the five electrical engineering and computer engineering students on this team are also part of Space Concordia, so it’s easy to see why they’d want to work on a CubeSat — a miniaturized satellite for space research.

“Space Concordia’s mission is to carry out a scientific experiment in space, so our project is to power it,” says Nathaly Arraiz, team spokesperson. “We used solar panels and stored the power in batteries. Plus, we needed to build an on-board computer that is self-sufficient and able to reboot and fix itself.”

Arraiz points out that the team had to work within strict material limitations because of the harsh conditions in Space. “It’s in a vacuum and it gets really hot and cold, and there’s radiation. But we tested our unit in a vacuum chamber and we froze it, but it still worked.”

The sporty team of electrical engineering students behind this project aimed to create a system that can determine how much power is applied by a cross-country skier on his or her skis and poles.

The sporty team of electrical engineering students behind this project aimed to create a system that can determine how much power is applied by a cross-country skier on his or her skis and poles.

Smart sport technology for cross-country skiing

It’s like a Fitbit for your skis … only better. The sporty team of electrical engineering students behind this project aimed to create a system that can determine how much power is applied by a cross-country skier on his or her skis and poles.

“There are a lot of moving parts, literally, so we needed to create hardware and software,” says Alexandre Picotte, team spokesperson.

“We designed four printed circuit boards to collect measurements from two different angles of the poles, the ground speed, force on the poles and back force on the skis. We were able to store our data in a SD card, then our software was able to process that data to display the total power produced by our skier. We wanted to make an app, but we didn’t get there yet.”

Find out more about Concordia’s Capstone engineering design project.