Concordia students build electron accelerator

Jad Saleh and his teammates set out to accomplish something completely different for the Capstone Engineering Design Project that mechanical engineering students at Concordia must complete in their final year of study.

“We wanted to do something that hadn’t been done before and that would leave our legacy at Concordia,” says team leader Saleh. “And we’ve been successful!”

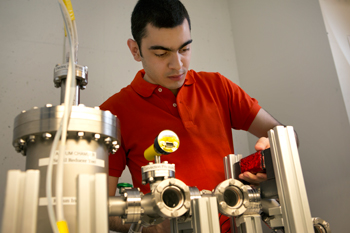

Saleh, along with Giovanni Fancello, Andrew Farag, Sabrina Ibarra, Stephen Jacobs and Nicholas Zacchia, chose to design and construct a linear particle accelerator.

Linacs – as they’re often called for short – increase the velocity of charged subatomic particles with applications such as X-ray machines and radiation therapy. The most famous one is the Large Hadron Collider at the CERN European Organization for Nuclear Research in Switzerland. Saleh’s team decided to design and build a mini electron gun accelerator and call it MEGA, short for Mini-Electron Gun Accelerator.

Associate professor Rolf Wüthrich suggested the idea (along with several others) to the team. He and PhD candidate Andrew Morrison were in charge of supervising the students as they used the research-and-design project to put their theoretical knowledge to practical use in solving an industrial need.

The team decided to take on the project despite the many challenges. It required the six students to learn about electrical systems, physics and particle accelerators in addition to mechanics. It would also cost $25,000 to build with only $750 provided by the Department of Mechanical and Industrial Engineering.

Everyone worked to find sponsors to provide funding or to donate sample equipment. Wüthrich, along with associate professor Mamoun Medraj, dug into their own pockets. TRIUMF, Canada’s national laboratory for particle and nuclear physics, also helped out.

Dealing with radiation and high voltages required the team to go through special training and simulation exercises to ensure their safety and limit their radiation exposure.

After working on the project for at least four hours every day, and sometimes as many as 14 hours on Saturdays and Sundays, the team saw the first signs of success in early 2012.

“It just felt amazing! We’ll never forget the first time we got it to work,” says Saleh. “I was standing outside the lab and all I heard was yelling and screaming, and then the doors opened and two of my team members shoved me in the lab and asked me to pull out my phone with its very good camera to start videotaping the results we were getting. It was just an unbelievable feeling! ”

Improvements continue to be made so that MEGA will eventually be used as a research tool by Wüthrich and his Electrocatalytic Green Engineering Group for their research on improving fuel cells.

The students have enjoyed some media fame for their capstone project, with CBC’s Daybreak and The Gazette interested in what the team believes is Montreal’s only linac.

Media outlets aren’t the only ones taking notice. The team has been awarded the Richard Cheng Design Award for Mechanical Engineering by Concordia’s Department of Mechanical and Industrial Engineering. It has also been selected to represent Concordia at the 2012 international congress of the Canadian Society of Mechanical Engineering on June 4.

The team recently attended the Canadian Undergraduate Technology Conference in Toronto to present their project. The students have also been invited to the Canadian Light Source – home of one of the world’s largest particle accelerators – in Saskatoon to demonstrate their project and tour the synchrotron research facility.

Their effort has also been entered into the Project of the Year competition staged by Dassault Systèmes for the best school- or home-projects created using the company’s software. People can vote for their favourite project on the company’s Facebook page. The winners will receive prizes and be featured on a calendar.

As project manager, Saleh is ecstatic about the outcome. “It feels great that we were able to lay out a plan and design and stick with them and the deadlines that we set,” he says. “And that putting our ideas together worked out perfectly.”

Watch the video:

Related links:

• Vote for the team in the Project of the Year competition

• MEGA

• MEGA’s creators

• "Recognizing student achievement in engineering" — NOW, May 1, 2012

• Department of Mechanical and Industrial Engineering: