STEM SIGHTS: The Concordian who is developing robots for heart surgery

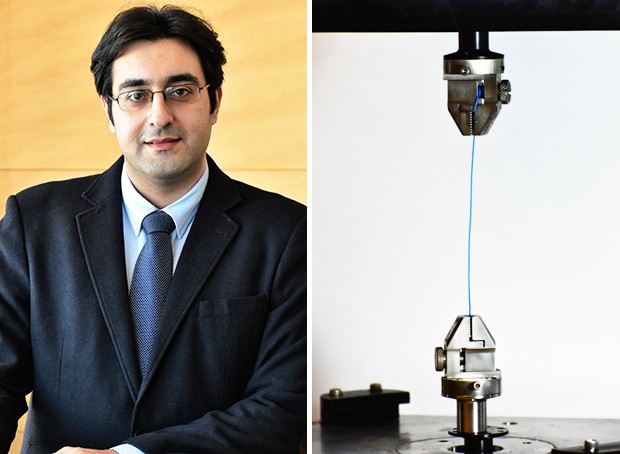

Amir Hooshiar (left) and (at right) a cardiac guide wire being tested to measure its mechanical properties.

Amir Hooshiar (left) and (at right) a cardiac guide wire being tested to measure its mechanical properties.

Would you let a robot into your heart?

Surgeons are now capable of performing complex and minimally invasive surgical procedures with the assistance of robotic technologies. A major challenge in using robots is that surgeons do not have a sense of touch while performing an operation.

Amir Hooshiar, a researcher at Concordia’s Tactile Sensors Laboratory who's pursuing his PhD in mechanical engineering, is developing the technology to help doctors “feel” what the robot is doing — mimicking the conditions of manual surgery.

'Assistive technologies are necessary'

What result are you looking for with your research at Concordia? And what impact could you see it having on people’s lives?

Amir Hooshiar: Cardiac diseases are the top cause of death globally. Minimally invasive and robot-assisted cardiac surgeries are growing rapidly to replace open-heart surgeries.

During the last five years, robot-assisted cardiac interventions have drawn new horizons for safe and effective treatment for cardiac diseases. Forecasts estimate promising global growth for robot-assisted cardiac interventions over the next two decades.

This technology is intended to be used during robot-assisted cardiovascular surgeries. During such minimally invasive surgeries, surgeons lose their haptic (or touch) perception. Therefore, assistive technologies such as haptic feedback systems are necessary to replicate a sense of touch for doctors.

This feedback should be based on measuring the interaction between the robot and the patient’s body. In my research, this interaction comes in the form of contact forces between the catheter and the patient’s vessels, and is estimated using image processing, mechanical analysis, augmented visual feedback and haptic feedback.

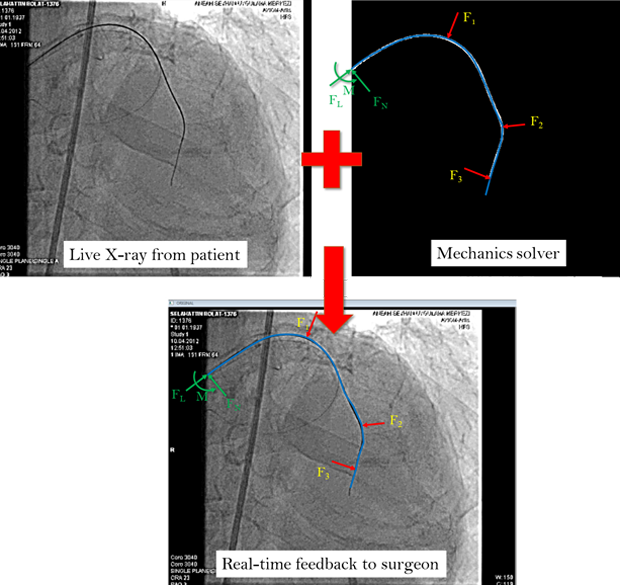

How does this specific image (above) relate to your research?

Amir Hooshiar: It shows three steps: medical image processing, mechanical analysis and augmented reality feedback to a surgeon during robotic cardiac surgery.

For any frame of the X-ray image from the patient’s chest, the shape of the catheter (a thin tube) is identified and the external forces are estimated. The original X-ray image is then augmented with the results, providing visual feedback and force-feedback to the surgeon.

This allows the surgeon to “feel’ the interaction between the body and the catheter on the robotic controls.

What are some of the major challenges you face in your research?

AH: Cardiac catheters, which appear as a dark line in the X-ray image, are structurally highly flexible and exhibit non-linear, or difficult to predict, mechanical behaviour.

This has complicated the modelling and analysis parts of my research. Also, anatomic variations, access to the medical imaging repositories and datasets, consideration of medical ethics, and time constraints for collaborating with medical experts and surgeons are some of the other significant challenges.

In which key areas could your work be applied?

AH: The results of this research could be applied in the design and development of different medical devices for minimally invasive surgeries. Other industries in which this technology is applicable would be the oil industry (for drilling technology), polymer processing (for extrusion) and electrics technology (for wire drawing).

What inspired you to study this subject and to get involved in this field?

AH: The first time I noticed the lack of this technology was during my first semester at Concordia. An alumnus from the BioRobotics and Tactile Sensors Laboratory was in charge of the design and development of the first commercial robotic cardiac intervention platform for a US-based company. My current research is partially inspired by the field needs identified by him.

I also attended the CREATE program for surgical innovation. This opportunity facilitated my presence at most of the major hospitals in Montreal, including the Montreal General Hospital and the Glen. The clinical needs and feedback I received from surgeons and researchers at McGill University also shaped my current research.

How can interested students get involved in this line of research?

AH: My field of research is highly clinics-oriented. This mandates having an engineering understanding of the human body. Researchers from different disciplines of engineering could get involved in various aspects of this line of research, including image processing, noise reduction, the biomechanics of tissues, robot control, haptic feedback system design and design optimization.

What do you like best about being at Concordia?

AH: I like the multicultural community of Concordia. The friendliness of the staff, especially in the Department of Mechanical and Industrial Engineering (MIE), is a motivator for any student and researcher.

Biomedical research is intrinsically an interdisciplinary field. The diversity of the scientific community at Concordia, along with the inter-university and industry-collaboration programs, makes it one of the most suitable places for researchers interested in biomedical research.

During the last 18 months of my PhD program, I got involved in three industry-related research projects, was nominated for a Vanier scholarship and an international FRQNT merit scholarship from Concordia, and attended the CREATE program.

This never could have happened without the support of my supervisor and the cooperation of the administration and staff at Concordia.

Find out more about the Department of Mechanical and Industrial Engineering at Concordia University.