Spark Assisted Chemical Engraving (SACE)

A lean innovative technology to micro-machine glass for ultra-customized parts meeting the demand of Industry 4.0

Micromachining glass

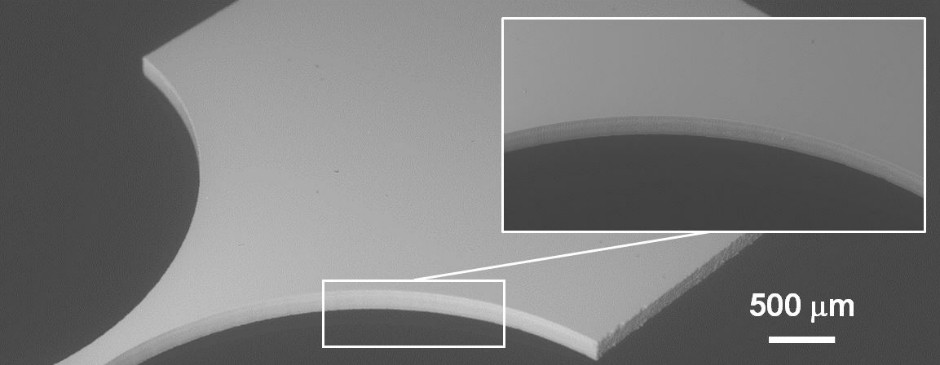

Spark Assisted Chemical Engraving (SACE) is a hybrid technology that combines chemical and thermal mechanisms. The machining technology preserves the optical transparency of glass while machining burrs- and cracks-free without leaving any deposits on the surface. Structures with aspect ratios of up to 1:10 can be realized.

SACE is based on thermally assisted etching of glass. Micro-holes with a depth of millimetres can be drilled in a few seconds and channels of several hundred microns deep can be produced without difficulty. It is also possible to cut glass over a thickness of a few millimeters. All these machining methods can be realised directly, without any intermediate process.

Our objective is to increase the fundamental knowledge about material removal process with the aim to increase repeatability and precision of machining and develop strategies to functionalise glass during machining.

Applications

Medical tech

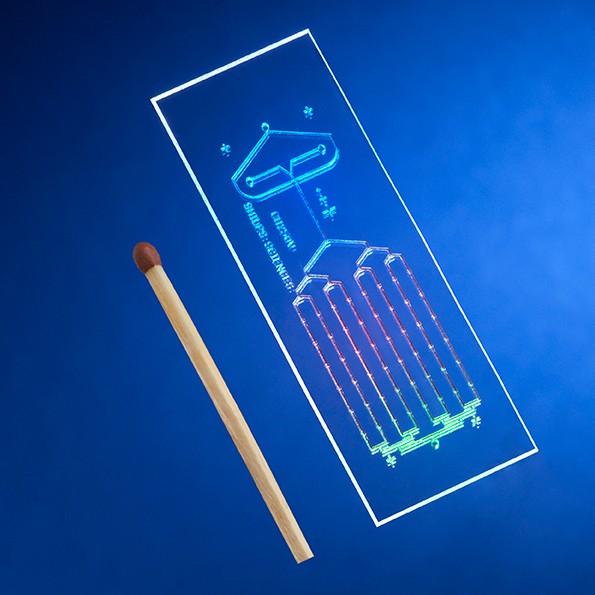

Lab-On-Chip

Multilayer chips

Micro- to Macro-world interfaces

Micro-cutting

Watch industry

Watchglass cutting

Inner parts

Anti-counterfeiting marks

Localized glass strengthening

Consumer electronics

Drilling through glass vias

Micro-cutting of glass

including thin (<300μm)

Micro-cutting of hardened glass

Rapid prototyping

Industrial R&D

Fundamental Research

Surface engineering